The Process of Making Steel Developed by Henry Bessemer

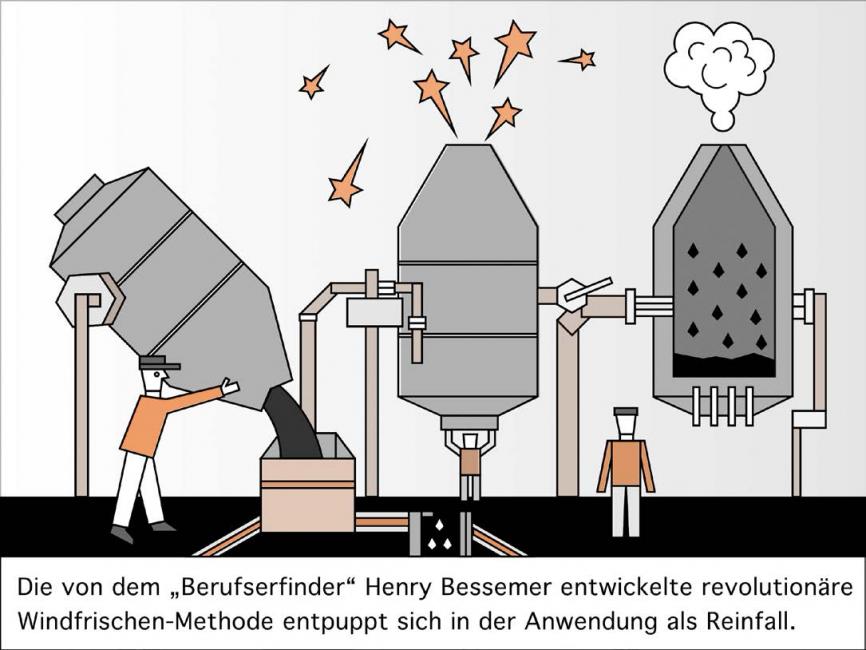

During the Crimean War Bessemer invented an elongated artillery shell that was rotated by the powder gases. Patented in 1855 the Bessemer process decreased the cost of steel from 5060t 8095t to 67t 911t hand-in-hand with vast increases in scale and speed.

The Bessemer Process Environment Society Portal

Bessemer patented a decarbonization process utilizing a blast of air in 1855.

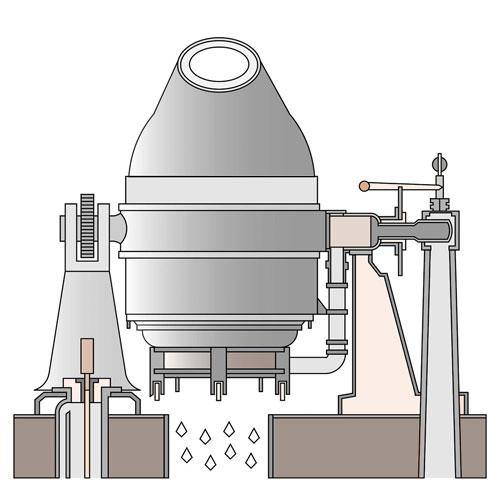

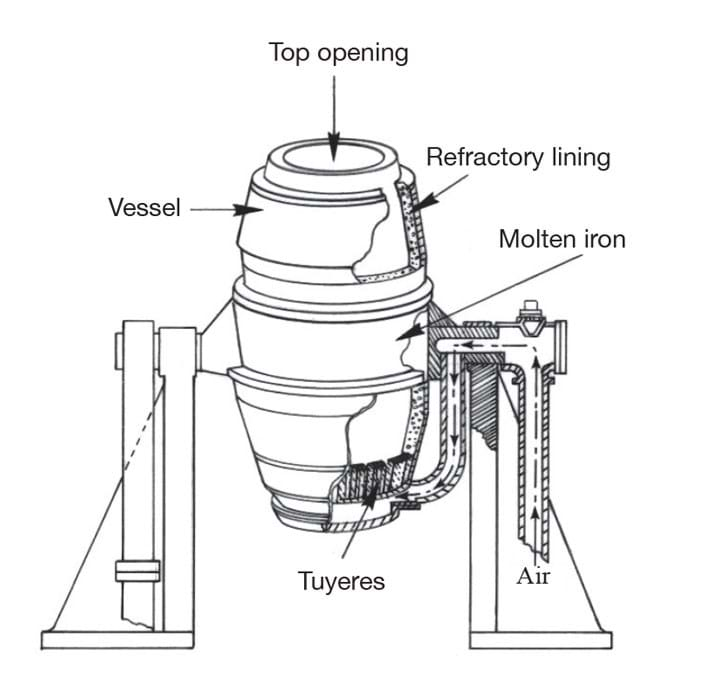

. Bessemer process the first method discovered for mass-producing steel. Modern Steel Modern steel is made using technology based on Bessemers process. To create the Bessemer Process he invented a large pear-shaped receptacle called a converter and utilized a blast of air in a de-carbonization process to create the steel from iron.

Though named after Sir Henry Bessemer of England the process evolved from the contributions of many investigators before it could be used on a broad. Largely obscured today by reclamation projects pine trees and kudzu the mining districts of Alabama are the remnants. The material was hard would take an edge and was used almost entirely for cutting tools.

It was named after the British inventor Sir Henry Bessemer who worked to develop the process in the 1850s. The Bessemer Steel Process was a method of producing high-quality steel by shooting air into molten steel to burn off carbon and other impurities. The Bessemer Steel Process was a method of producing high-quality steel by shooting air into molten steel to burn off carbon and other impurities.

The Bessemer process was the first inexpensive industrial process for the mass production of. Science also led to the publication of Rachel Carsons book Silent Spring in the 1960s thereby giving rise to environmental consciousness. The Bessemer process was the first industrial steel-making process by using pig iron in its molten state developed by English inventor Sir Henry Bessemer in 1856.

Bessemer Process A process developed in England about 1850 by Sir Henry Bessemer for making steel by blowing air under pressure through molten pig iron contained in a suitable vessel whereby a portion of the iron most of the silicon and manganese and practically all the carbon are eliminated by oxidation. The only material known as steel was made by adding carbon to pure forms of wrought iron also by slow and discontinuous methods. IF the industrial revolution was built on steel then the father of the industrial revolution was Henry Bessemer.

The open-hearth process made possible the production of steel in great quantities and large dimensions T In the 1870s the internal combustion engine was developed in. This in turn provided steel at relatively low cost to various industries. Steel Making and the Bessemer Process The Bessemer Process was created in England by Henry Bessemer in 1855 and brought into production by Henry Bessemer in 1860.

A system akin to the Bessemer process has existed since the 11th century in East Asia. Wertime have described the method as a. Bessemer process the first method discovered for mass-producing steel.

On the making of the first steel ingot Bessemer said. Henry Bessemer in full Sir Henry Bessemer born January 19 1813 Charlton Hertfordshire Englanddied March 15 1898 London inventor and engineer who developed the first process for manufacturing steel inexpensively 1856 leading to. This made steel easier quicker and cheaper to manufacture and revolutionized structural engineering.

By developing a one-step process to make low-cost steel Henry Bessemer provided the raw materials from which our modern world is made. By revolutionizing the steel industry the Bessemer process helped to spur on the Industrial Revolution. Sinologist Joseph Needhamand historian of metallurgy Theodore A.

An example of this is the Bessemer process the first inexpensive industrial process for the mass production of steel. Melting of metal typically is accomplished with coal and. Developed by British manufacturer Henry Bessemer and American ironmaker William Kelly around 1850.

It is hard to imagine life today without these things. Economic historian Robert Hartwell writes that the Chinese of the Song Dynasty 960-1279 CE innovated a partial decarbonization method of repeated forging of cast iron under a cold blast. In 1856 Henry Bessemer 1813-1898 developed a new method for manufacturing steel.

I well remember how anxiously I awaited the blowing of the first 7-cwt. Bessemer had been trying to reduce the cost of steel-making for military ordnance and developed his system for blowing air through molten pig iron to remove the impurities. In the US where natural resources and risk-taking investors were abundant giant Bessemer steel mills sprung up to drive the expanding nations rise as a dominant world economic and industrial leader.

Charge of pig iron. It was the Bessemer process that made steel available in industrial quantities at an affordable price. In this method air is blown through the molten iron to remove the impurities present by oxidation which increases the temperature of the molten iron.

The Bessemer process made possible the manufacture of large amounts of high-quality steel for the first time. This process is known as the Modern Steel Production Process.

The Bessemer Process What It Is And How It Changed History

The Bessemer Process What It Is And How It Changed History

No comments for "The Process of Making Steel Developed by Henry Bessemer"

Post a Comment